- Home

- About Us

- Principals

- Products

- Raw Materials

- Water Based Alkyd Resins

- WorléeSol E 150 W

- WorléeSol E 280 W

- WorléeSol E 330 W

- WorléeSol E 530 W

- WorléeSol E 927 W

- WorléeSol SE 420 W

- WorléeSol NW 410

- WorléeSol NW 474

- WorléeSol 07 A

- WorléeSol 30

- WorléeSol 31 A

- WorléeSol 31 C

- WorléeSol 37 C

- WorléeSol 61 A, E, F, P

- WorléeSol 64 E

- WorléeSol 65 A, E

- WorléeSol 68 A

- WorléeSol 84 C

- WorléeSol 85 A

- Solvent Based Alkyd Resins

- WorléeKyd AC 2550, AC 2551

- WorléeKyd LH 3702

- WorléeKyd MH 439

- WorléeKyd S 3001

- WorléeKyd SM 400

- WorléeKyd B 845

- WorléeKyd BS 830

- WorléeKyd BSA 5015

- WorléeKyd B 6301

- WorléeKyd B 865 nv

- WorléeKyd B 868

- WorléeKyd L 7904

- WorléeKyd P 151

- WorléeKyd S 365 mv

- WorléeKyd SD 7003

- WorléeKyd B 865 U nv

- WorléeKyd S 6003

- WorléeKyd SD 6403

- WorléeKyd V 5241 U

- WorléeKyd C 641

- WorléeKyd C 743 hs

- WorléeKyd SH 380

- Acrylic Resins

- WorléeCryl A 1220

- WorléeCryl A 2210

- WorléeCryl A 2218

- WorléeCryl A 2335

- WorléeCryl A 2445

- WorléeCryl A 2230 W

- WorléeCryl A 2241 W

- WorléeCryl L 1870

- WorléeCryl L 2380

- WorléeCryl L 2822

- WorléeCryl 7120

- WorléeCryl 7135

- WorléeCryl 7158

- WorléeCryl 7189

- WorléeCryl 7450

- WorléeCryl 7461

- WorléeCryl 7463

- WorléeCryl 7712 H

- WorléeCryl 7712 W

- WorléeCryl 7123

- Zinpol 132

- Zinpol 146

- WorléeCryl 8222

- WorléeCryl 8290

- WorléeCryl 8273

- WorléeCryl 8043

- Thixotrophic Resins

- Epoxy Esters

- Polyester Resins

- Maleic and Fenolic Modified Rosin Esters

- Wet Paint Additives

- WorléeAdd 100

- WorléeAdd 101

- WorléeAdd 311

- WorléeAdd 315

- WorléeAdd 327

- WorléeAdd 340

- WorléeAdd 351

- WorléeAdd 352

- WorléeAdd 356

- WorléeAdd 361

- WorléeAdd 410 N

- WorléeAdd 458

- WorléeAdd 486

- WorléeAdd 700

- WorléeAdd 720

- WorléeAdd 2000

- WorléeAdd 2030

- Resiflow FL 2

- Resiflow FM 4

- Resiflow W 52

- Resiflow W 5200

- WorléeProtect 1528

- WorléeAdd 6226

- WorléeAdd 685

- WorléeAdd 603

- WorléeAdd 6235

- WorléeAdd VP 6236

- Special Adhesion Primers

- Powder Coating Additives

- Functional Pigments

- Special Raw Materials

- Water Based Alkyd Resins

- Dispersion

- Laboratory and Pilot Plant

- Production

- Accessories

- Corrosion

- Appearance

- Film Application

- Manual Film Applicators

- Baker Type 4-Sided Film Applicators

- Prismatic Type 4-Sided Film Applicator

- Quadruplex Film Applicator

- Dual Reservoir 4-Sided Film Applicator

- Octoplex Film Applicator

- Single Gap Bird Type Film Applicator

- Triple Reservoir Film Applicator

- Sagging & Levelling Applicator

- Application Beds

- Adjustable Film Applicator

- Cube Applicator

- TQC Automatic Film Applicator

- TQC Automatic Film Applicator -Compact

- K-Hand Coater / K-Bar

- K-Control Coater K101/202

- K-Lox Anilox Roller

- Esiproof - Anilox Roller

- K-Printing Proofer - KPP Gravure / Flexo

- K303 MultiCoater

- Paste Ink Proofer

- Flexiproof 100

- GP100 (High speed gravure unit)

- Rotary Coater

- VCM-Versatile Converting Machine

- Automatic Panel Sprayer (4500N, 4700N)

- Manual Film Applicators

- Viscosity

- Film Thickness

- Adhesion

- Hardness, Elasticity & Impact Resistance

- Rub & Scrub Resistance

- Surface Preparation

- General Laboratory Equipments

- Test Charts and Standard Panels

- Curing and Drying

- Other Instruments

- Raw Materials

- Contact

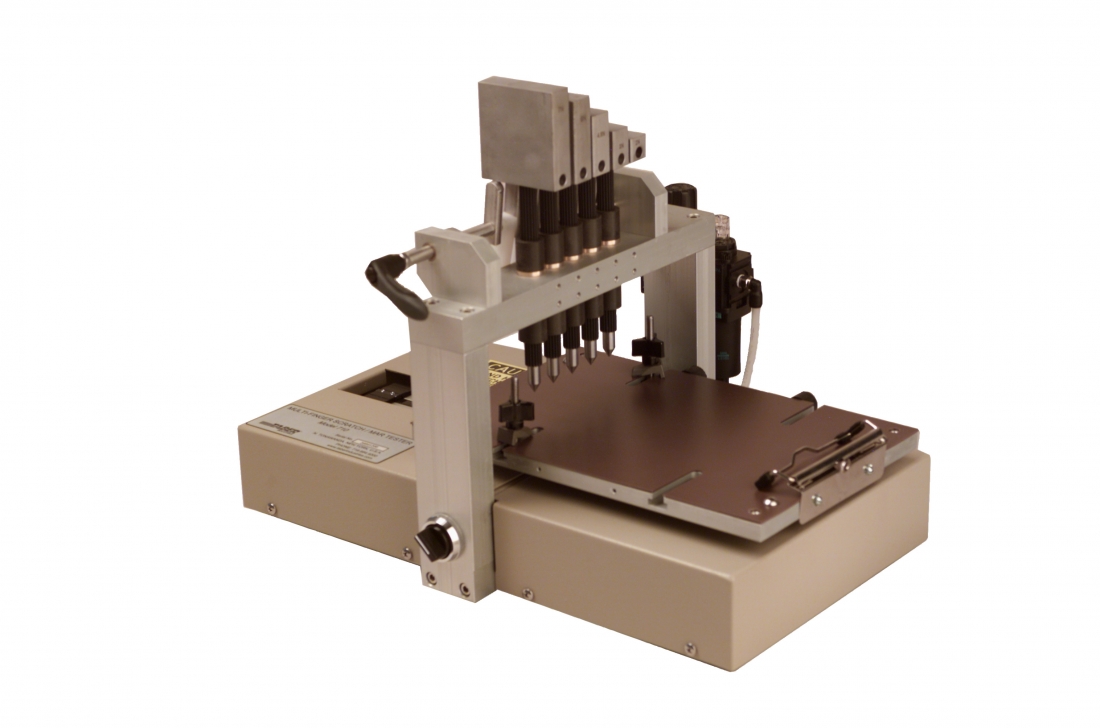

Taber Multi-Finger Scratch/Mar Tester

The TABER ® Multi-Finger Scratch / Mar Tester is used to measure the relative resistance or susceptibility of a material surface to scratching, marring, gouging, scraping, engraving and other similar physical damage that can’t be classified as ordinary wear.

The TABER ® Multi-Finger Scratch / Mar Tester is used to measure the relative resistance or susceptibility of a material surface to scratching, marring, gouging, scraping, engraving and other similar physical damage that can’t be classified as ordinary wear.

The Multi-Finger Scratch / Mar Tester includes a pneumatically driven, move-able platform to which the test specimen is mounted. The platform moves in a linear fashion, and is operated by a control knob for single or multiple pass testing. An electronic timer displays the rate of speed, which can be controlled by reducing or increasing air pressure.

A gantry supports five independent splined-fingers, which provide a constant, vertical load on interchangeable scratch tips. The gantry system includes a handle to raise and lower the arms. In addition, five support rests are incorporated to allow one or more arms to be moved to an upright, rest position such that the arm does not contact the specimen during testing.

Individual weights of varying loads mount to the top of each arm finger to exert a standard force on the surface of the test material. Each instrument includes a weight set of 2N, 3N, 4N, 5N, 6N, 7N, 10N, 15N and 20N loads. Optional weights sets are also available consisting of either 4N, 8N, 9N, 13N or 8N, 13N, 18N weights. In additional, an optional weight of 25N or Precision Weight Kit to achieve 0.6N loads are available.

Although flat specimens up to 22mm thick are normally tested, the ‘free-floating’ arms fingers enable you test evaluate slightly contoured specimens provided they are rigid or adequately supported. A spring-loaded specimen holder is standard and can be mounted to the end or side of the moveable platform for greater flexibility. To mount contoured specimens, two specimen hold-down clamps are provided. An optional 5mm spacer set is available to raise the gantry to accommodate specimens that are greater than 22mm thick.

Order Id

Description

980710

Multi-Finger Scratch and Mar Tester incl.:

• Spline Shaft ‘Finger’ Assembly (5 ea.)

•9 pc. Weight Set (2N, 3N, 4.5N, 5N, 6N, 7N, 10N, 15N, 20N)

• Scratch Tips with 1.0 mm dia. hemisphere (5 ea.)

• Mar Tips with 7.0 mm dia. hemisphere

• Specimen Clamp (2 ea.)

• Specimen Platform Protective Guard (installed)

• Operating Instructions

• Spline Shaft ‘Finger’ Assembly (5 ea.)

•9 pc. Weight Set (2N, 3N, 4.5N, 5N, 6N, 7N, 10N, 15N, 20N)

• Scratch Tips with 1.0 mm dia. hemisphere (5 ea.)

• Mar Tips with 7.0 mm dia. hemisphere

• Specimen Clamp (2 ea.)

• Specimen Platform Protective Guard (installed)

• Operating Instructions

Multi-Finger Scratch / Mar Tester -Weights

132740

Precision Weight Kit (mount to spline shaft to achieve 0.6N load)

132351-x

Multi-Finger Scratch / Mar Tester Weight – 1N, 2N, 3N, 4N, 4.5N, 5N, 6N, 7N, 8N, 9N, 10N, 12N, 12.5N, 13N, 15N, 18N, 20N, 25N (referenced in Chrysler LP-463DD-18-01)

135085

Optional Weight Set – 4N, 8N, 12N (referenced in Chrysler LP-463-DD-18-01)

134297

Optional Weight Set – 4N, 8N, 9N, 12N

132401

Optional Weight Set – 8N, 13N, 18N (referenced in GMN3943)

Multi-Finger Scratch / Mar Tester –Scratch Tools

132347

Scratch Tip, 1.0 mm diameter hemisphere (ea.)

132532

Scratch Tip, 1.0 mm diameter hemisphere (set of 5)

132348

Mar Tip, 7.0 mm diameter hemisphere (ea.)

132533

Mar Tip, 7.0 mm diameter hemisphere (set of 5)

Various

• Conical Scratch Tip, 0.10 mm Diameter [0.05 mm RAD] (9g)

• Conical Scratch Tip, 0.25 mm Diameter [0.125 mm RAD] (9g)

• Conical Scratch Tip, 0.30 mm Diameter [0.15 mm RAD] (9g)

• Conical Scratch Tip, 0.40 mm Diameter [0.20 mm RAD] (10g)

• Conical Scratch Tip, 0.50 mm Diameter [0.25 mm RAD] (10g)

• Conical Scratch Tip, 0.60 mm Diameter [0.30 mm RAD] (10g)

• Conical Scratch Tip, 0.75 mm Diameter [0.375mm RAD] (10g)

• Conical Scratch Tip, 1.0 mm Diameter [0.50 mm RAD] (10g)

• Conical Scratch Tip, 0.25 mm Diameter [0.125 mm RAD] (9g)

• Conical Scratch Tip, 0.30 mm Diameter [0.15 mm RAD] (9g)

• Conical Scratch Tip, 0.40 mm Diameter [0.20 mm RAD] (10g)

• Conical Scratch Tip, 0.50 mm Diameter [0.25 mm RAD] (10g)

• Conical Scratch Tip, 0.60 mm Diameter [0.30 mm RAD] (10g)

• Conical Scratch Tip, 0.75 mm Diameter [0.375mm RAD] (10g)

• Conical Scratch Tip, 1.0 mm Diameter [0.50 mm RAD] (10g)

132533

• Diamond Tool Holder [includes 121006 conical diamond tool w/90° 3 mil (0.003”) radius point]

• Diamond Tool Holder [includes 121006-1 conical diamond tool w/90° 3.5 mil (0.0035”) radius point]

• Diamond Tool Holder [includes 121006-2 conical diamond tool w/60° 0.3 mm radius point]

• Diamond Tool Holder [includes 121006-1 conical diamond tool w/90° 3.5 mil (0.0035”) radius point]

• Diamond Tool Holder [includes 121006-2 conical diamond tool w/60° 0.3 mm radius point]

134581

5 mm Spacer Set (2 each)

132455

Specimen Hold-down Clamp, replacement (ea.)

132451

Specimen Platform Protective Guard, replacement

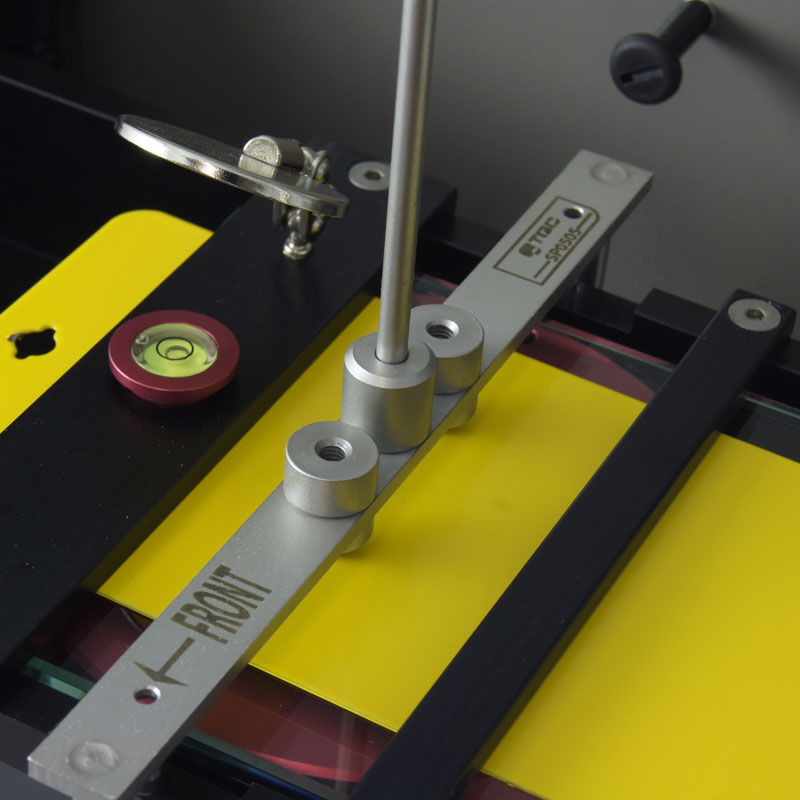

Taber Shear / Scratch Tester

Tester to evaluate resistance to shearing, scratching, gouging, marring, scraping and engraving on a variety of flat, rigid specimens

Taber Shear / Scratch Tester is a motorised instrument for testing the resistance to scratching of materials. A sample plate rotates while a conical diamond point is pressed on the sample plate. The relation between the depth of the scratch and the applied (pre-set) pressure indicates the hardness.

Complies with virtually all relevant international standards such as Normen:

ASTM C217 / C217M • DIN 53 799 • DIN 66 861-4 • EN 438-2 • EN 13310 • EN 14323 • EN 14565 • EN 14688 • 0096Z-SEC-A000 (Honda) • 7710Z-SCC-9000 (Honda) • ISO 4586-2 • ISO 15695 • JIS K 6902 • Terrazzo 90322-9E-1 • TSL 2105G (Toyota) • TSL 3610G (Toyota) • UNI 9428

Order Id

Description

980551

Model 551, Taber Shear / Scratch Tester - 5 rpm (230V,50 Hz), incl.:

• Scale Beam with two Calibrated Weights (500 gram ea.)

• Protective Case for Scale Beam

• Conical Diamond Tool (139-55)

• Contour Shear Tool (S-20)

• Diamond Standardization Plates (pkg. 2)

• Spirit Bubble Level

• Measuring 10x Magnifier

• Hex Wrench

• Operating Instructions

• Scale Beam with two Calibrated Weights (500 gram ea.)

• Protective Case for Scale Beam

• Conical Diamond Tool (139-55)

• Contour Shear Tool (S-20)

• Diamond Standardization Plates (pkg. 2)

• Spirit Bubble Level

• Measuring 10x Magnifier

• Hex Wrench

• Operating Instructions

132719

Scale Beam Height Extension Kit for Model 550/551 – for

testing specimens up to 40 mm [includes scale beam adaptor;

stud extension and nut; set of 2 shim plates]

121006

Conical Diamond Tool with 90°, 3 mil (.003”) radius point

121006-2

Conical Diamond Tool with 60°, 0.3 mm radius point

121006-3

Conical Diamond Tool with 120°, 200 µm radius point

121008

Diamond Scratch Tool (cutting edge is the converging point from three sides and edges of a cube)

135124

Tungsten Carbide Scratch Tip with 60°, 0.25 mm diam. point

134872

Carbide Scratch Tip with 45°, 0.25 mm radius point per EN 14565

132796

Scratch Tip, 1.0 mm diameter hemisphere (ea.) {requires scale beam height extension kit}

121017

S-20 Contour Shear Tool, Tungsten Carbide

133582

S-20-3 Carbide Tool – similar to S-20 Contour Shear Tool but w/ no radius (meets Honda requirements)

132914

S-20-4 Carbide Tool – similar to S-20 Tool but with R2.6 mm

134306

Shear / Scratch Tester Scale Beam Calibration Verification Fixture

132618

Diamond Standardization Plates – PMMA, vacuum predried and sealed (pkg. 2)

134896

Scale Beam Fixed Weight (provides 1000 – 1500g load)

133659

Scale Beam Fixed Weight (provides 15N load)

134247

Scale Beam Modified Weight Set (converts scale to 0 – 50

gram range)

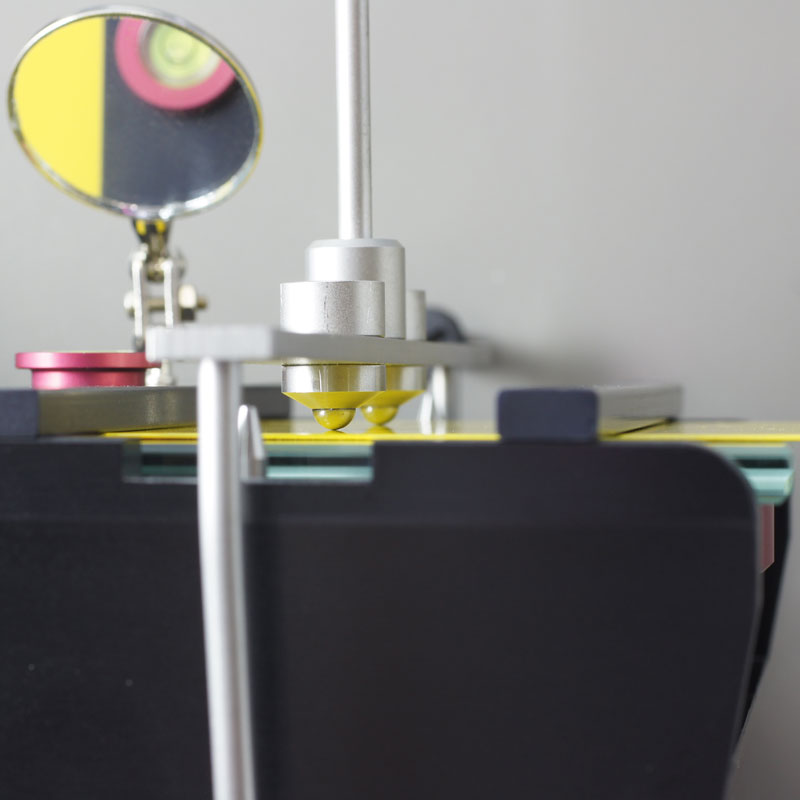

The TQC Pendulum Hardness Tester has a lot of unique features that ease defining hardness by the König and/or Persoz method as described in ISO 1522. Both methods work on the principle that the damping time of a pendulum oscillating on a sample indicates the hardness.

The instrument has an easy menu-driven interface with jog dial. The automated electronic counting mechanism is not affected by reflections from the surrounding area. The water-level is located on the test specimen, rather than on the instrument’s base. Once the instrument is leveled further calibration is not required. The gas-spring supported transparent draft cover allows easy access to all parts of the instrument.

TQC’s Pendulum Hardness Tester is a modular system. The instrument itself can be used for both the König and- Persoz method. Both pendulums should be ordered separately. After placing the correct pendulum, switching between the two measuring methods only takes a push of a button. The Pendulum is positioned fully automatically by means of a stepper motor. Also the release of the Pendulum is automated through electro-magnetic system. The end of a test is indicated by a visual and acoustic signal.

Order Id

Description

SP0500

TQC Pendulum Hardness Tester 230V, Pendulum base device, without Pendulum

SP0505

TQC König Pendulum for hardness test

SP0510

TQC Persoz Pendulum for hardness test