Drying Time Recorder

The new TQC Drying Time Recorder is a fully digitally controlled machine that operates conform the BK (Beck Koller) method

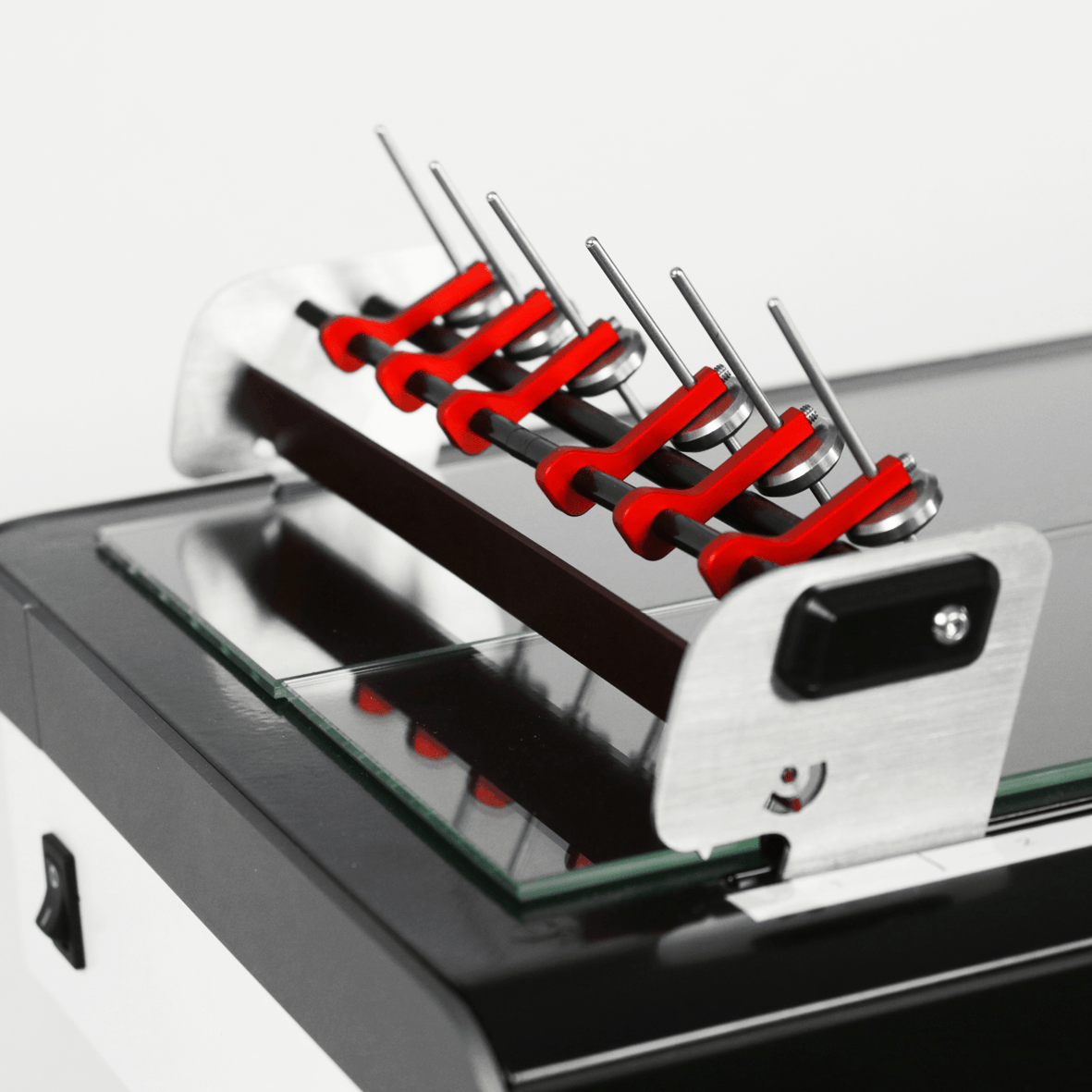

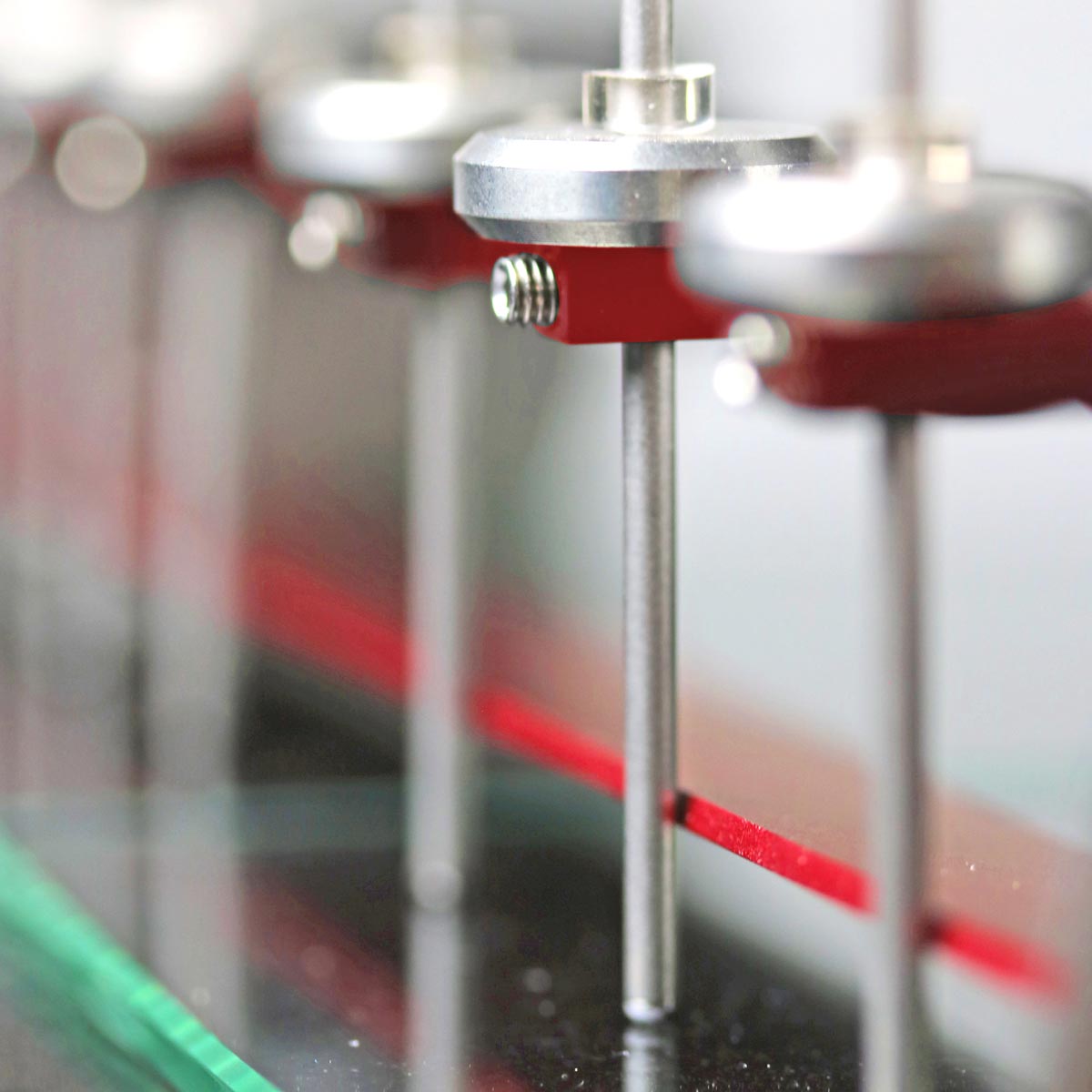

The TQC Drying Time Recorder is a fully digitally controlled machine to define the different stages in the drying process of paints and coatings. The TQC Drying Time Recorder operates conform the BK (Beck Koller) method. Defining the final result or checking intermediate stages is very easy by means of the clear digital display and the intuitive interface. The compact machine meets ASTM D5895, ISO 9117-4 and DIN EN 14022. The TQC Drying Time Recorder has six tracks, and comes with two robust and reusable glass beds of 100 X 350 X 3 mm. Optional are six narrow glass beds in special adapters.

The front panel of the TQC Drying Time Recorder is made out of clear glass, which is easy to clean and protects the display underneath it. The TQC Drying Time Recorder is powered by a safe 24 V DC power supply.

Standards: DIN EN 14022, ASTM D5895, ISO 9117-4

Temperature-friendly Design

The possibility to perform tests at temperatures as low as -20 °C is unique. The drive system is lubricant free, so there is no risk of lubricants that thicken at lower temperatures. The display is heated which enhances menu visibility at lower temperatures. These design features result in a wide operating temperature range from -20°C to +70°C (non-condensing), which makes it possible to perform tests in climate chambers.

Broad and flexible time range

A broad and flexible time range can be set varying from 1 minute up to 200 hours. This makes the TQC Drying Time Recorder suitable for fast drying waterborne coatings as well as very slow drying paints that may need days to dry. Time settings are very accurate, < 1 % of set time.

Where To Apply?

NAIL POLISH

Short Time Range

Because of the quick drying time of nail polish it wasn't possible to measure the drying time before. With the new drying time recorder you can set a time range starting from 1 minute.

WALL PAINT

Thick layers

Time range can be set up to 200 hours. This makes the TQC Drying Time Recorder suitable for very slow drying paints such as wall paint.

WATERBORNE COATINGS

Fast drying time

Water evaporates fast, that's why a short time range is necessary for measuring the drying time of waterborne coatings.

ADHESIVES

Drying time

Matter of course its important to know how long it takes before glue is all dried up. Use the new TQC Drying Time Recorder to measure this.TRIPLE I CONTROL® (INTELLIGENT ILLUMINATION INTERFACE)

Operating is very easy with the Triple i operating interface. This unique systems guide the operator through the interface of TQC lab-machines. At each step of the operating menu the interface detects which buttons are active and indicates these by means of an illuminated red centre. This results in a very intuitive operating system which is enhanced with information on the machine’s display.

TRIPLE RESERVOIR FILM APPLICATOR 90 | 150 MICRONS

TQC Film Applicator with 3 reservoirs. Ideal for applying paint with use of a TQC Automatic Film Applicator or Drying Time Recorder. This applicator can apply 2 pre-defined thicknesses, 90 and 150 microns.

QUESTIONS AND ANSWERS

Why does paint dry on the wall but does not harden when in the tin?

There are two basic mechanisms by which paints dry on the wall.

Many modern paints are largely water-based. As we know, water readily evaporates. However, the rate of evaporation of a liquid depends on the vapour pressure of that liquid above the surface. In a sealed tin of paint, a set vapour pressure is quickly established in the small headspace in the tin and the water in the paint does not evaporate and remains in the paint. But, when painted on the wall, the water can readily evaporate to leave a dried film of solid paint components behind – there is no build-up of water vapour pressure in a confined space as there is in the tin.

Other paints, especially those manufactured some time ago, are by contrast largely oil-based. Unlike water, the oil does not evaporate. These paints dry on the wall in a very different way, through a chemical reaction with the oxygen in the air. This causes the relatively small molecules in the oil to form much larger molecules which have a solid rather than liquid form (i.e. polymers are formed). In the sealed tin, oxygen is not available for this chemical reaction to occur, and the oil remains in its original, fluid (smaller molecule) form.

These two distinct mechanisms account for the contrasting behaviour of paints in a sealed tin and on a wall.

How does paint dry?

As the paint dries, a film is formed which adheres to the surface of the material to which it is being applied.

Emulsion paints dry by a physical process involving the evaporation of water followed by coalescence of the polymer droplets and their subsequent integration into a hard polymer matrix that acts as a binder for the pigment.

On applying gloss paints, the alkyd polymer cross-links by an oxidation reaction with oxygen in the air once the solvent has largely evaporated. This reaction is accelerated using salts of transition metals (for example, cobalt and manganese naphthenates). The transition metal ion (with variable oxidation state) catalyses cross linking of the polymer chains, producing a hard surface film to the paint.

How does gloss paint dry?

The binder or film former in gloss paint is called an alkyd resin. … When the solvent evaporates, the oxygen of the air interacts with the resin which results in the formation of cross links between the polymer molecules and produces a strong, dry film.

How long does it take for latex paint to dry?

How long does latex paint take to dry between coats? The majority of latex paints when applied at room temperature will be dry set-to-touch within one hour or less and may be recoated within four hours. Poor ventilation, low temperatures, thick films and high humidity will increase these times.

How long does it take for latex paint to cure?

A second or third coat can typically be applied within three to five hours. Because latex paint dries on the outside first, it takes at least 14 days for it to cure. If the paint is in an area with bad curing conditions, it could take up to 30 days.

How long does it take for Polycrylic to cure?

At least 3 coats are recommended. If unable to recoat within 1½ hours, wait at least 72 hours then lightly sand and recoat. Polycrylic™ dries to the touch in 30 minutes and can be handled after 1 hour. After final coat, allow 24 hours before normal use.

THE DIFFERENT DRYING STAGES

The ASTM D5895 – 03 and ISO 9117-4:2012identifies different drying time stages

I | Set-to-touch time

The stylus creates a pear- shaped mark at the top of the film. The paint does not flow anymore over the path created by the stylus and reveals the glass substrate.

Evaporation of the solvent or water results in a solidified film that no longer sticks to a finger at a light touch.

II | Tack-free time

The continuous track in the film ceases and the stylus starts to tear the film or leave a sharp edged or scruffy track.

Note: Coatings such as polyurethanes or two component epoxies may form a different butterfly- or kite shaped pattern here.

A tack-free condition is reached, light objects placed on the paint film will not stick.

III | Dry-through time

The stylus rides on the surface of the paint film and leaves no visual marks on the surface.

The paint film is not displaced or marked by pinching a coated panel between forefinger and thumb with a string force

IV | Dry-hard time

The stylus has risen out of the film and rides on the top. It leaves a small mark without damaging the body of the film.

The paint film is not displaced or marked by pinching a coated panel between forefinger and thumb with a medium force.